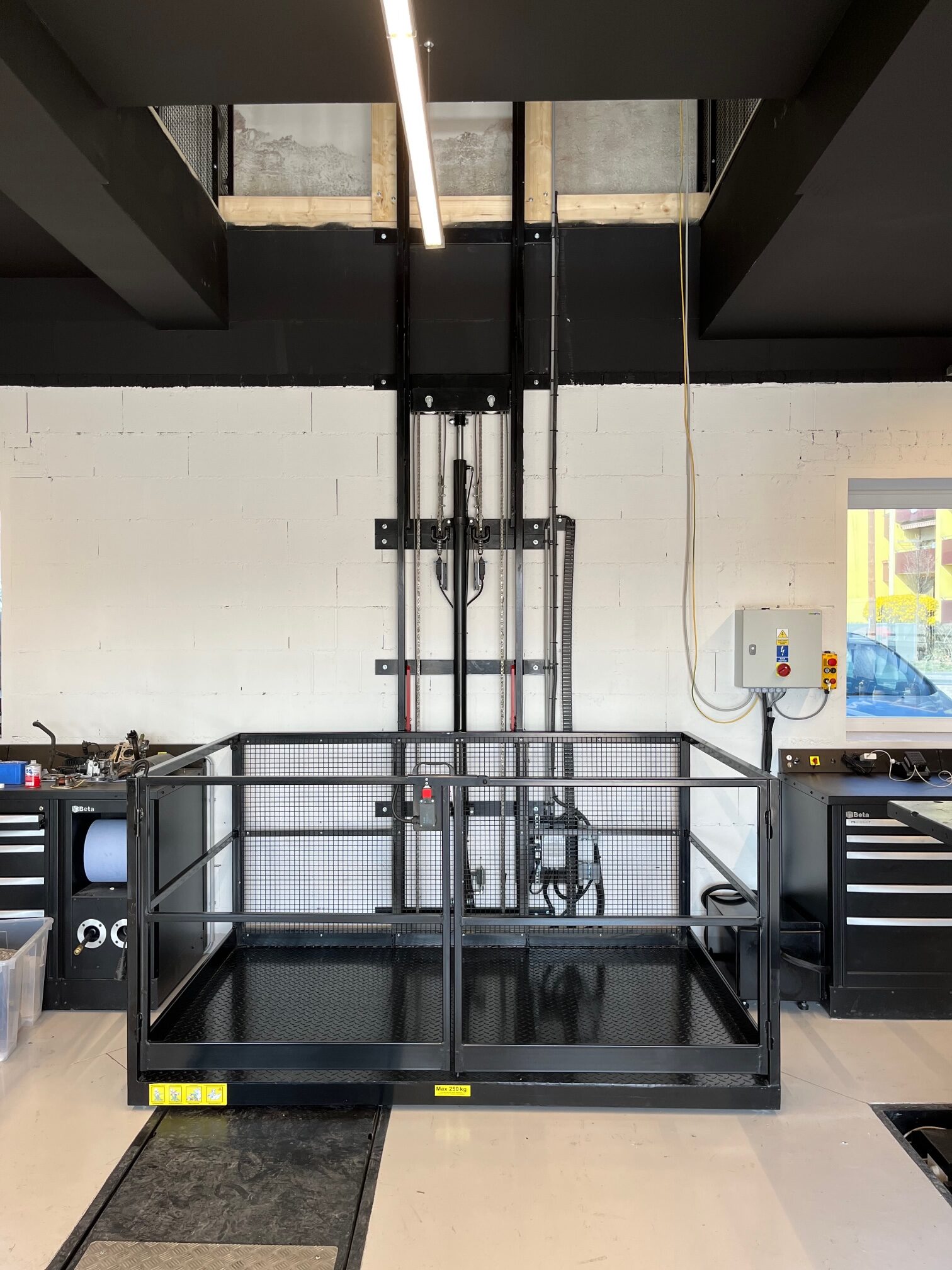

Freight lift without pit

The task in this project was to transport mopeds and other items to the upper floor using a freight lift. This sounds relatively simple and can be done with one lifting table or one column lifter be done in a closed shaft.

However, the customer also specified that no shaft could be built on the ground floor, i.e. directly in the workshop. The load lifter also had to do without a pit in the ground because the area had to remain partially usable.

In collaboration with the authorities and an authorized civil engineer, we found, installed and handed over a great lifting solution for our satisfied customer.

The load capacity of Freight elevator was relatively low at 250 kg - we can easily transport several tons here. The platform had a size of 2350 x 1500 mm. The level difference was 3900 mm. The access height is only 100mm and can be overcome using a ramp.

Column jack without shaft and without pit

Project planning & natural dimensions of the column lifter

In addition, we also measured the difference in level between the two floors so that we could get the right one load lifter could offer.

Delivery from the column jack

The hydraulic column jacks is already assembled in the factory and tested there. Depending on the size of the jack or depending on the local conditions (door sizes, accessibility, aisle widths, etc.), it may also happen that we deliver the platform with the railings dismantled.

Column jack without pit

Assembly doesn't just include unpacking, aligning and screwing on column lifter on the will, but also many other things.

In the background on the right you can see the unit (black, on the floor) and our control cabinet (white on the wall). We also position these in the desired locations after consultation with the customer. It is of course advisable to specify the position when ordering so that the hydraulic hose and cables are long enough.

We lay the cables surface-mounted or in the prepared empty conduits. If cable channels are provided, we use them.

The position of the control is chosen so that the customer can work well, but the standard specifications are also adhered to. Here a position at the lower stop, within the visible area of the system, was necessary. This means that the danger area under the platform can always be seen.

Upper stop secured

In this project, we built a grid wall on 2 sides at the upper stop - on the first floor. At the front we installed a gate with 2 leaves.

Due to the forced contact on the door, it can only be opened when the column lifter is at the top position. Likewise, he can Freight lift without a pit only drive off when the gate is closed.

This function is monitored by our controller.

There is no control unit at the upper stop because you cannot see the danger area under the platform from here. Operation from above is only permitted in a closed shaft.

Order lifting tables now

If you have any questions, please contact us immediately Contact on. We are happy!