Accessories for lifting tables

All our products can be equipped with a wide range of accessories to make your work easier or to increase the safety of your employees.

Many options are suitable for retrofitting scissor lift tables, but some must be considered when ordering the lift table.

Accessories are required for lifting tables when the standard version is no longer sufficient. Sometimes additional equipment is required because the customer's requirements require it, but often also because the lifting table standard EN1570-1 requires it. Trained staff is therefore absolutely necessary so that every procurement can be delivered exactly according to the standard. Our technicians are continuously trained on the news from our partners.

Accessories for our lift table models

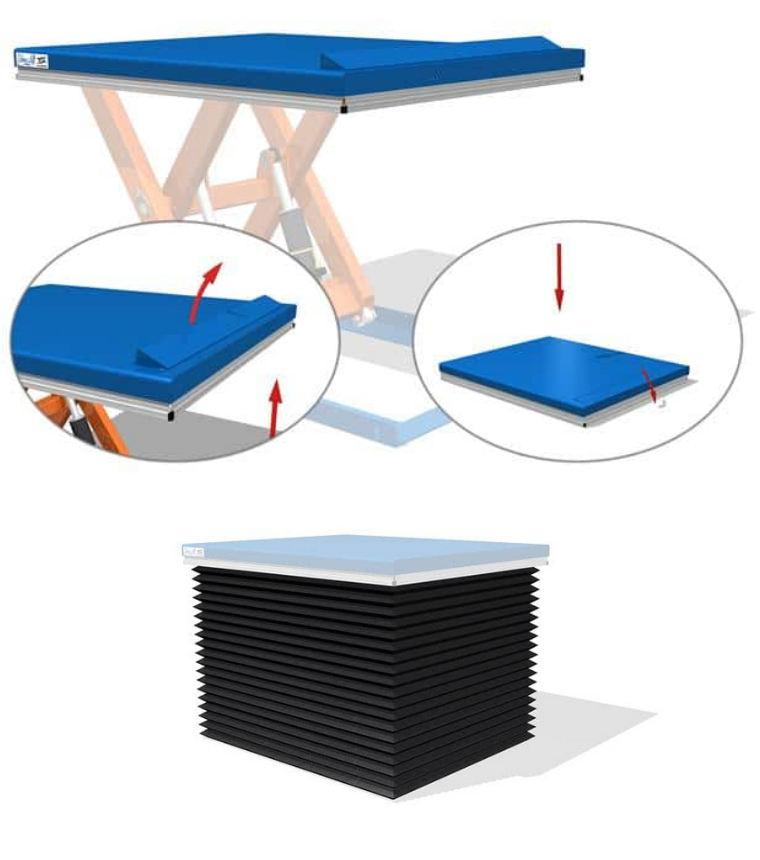

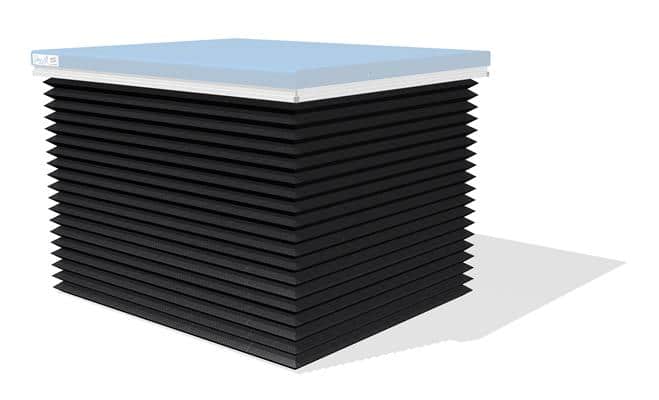

Bellows as underflow protection

The circumferential bellows is the best alternative to PVC roller blinds or protective grilles. This is installed under the platform behind the safety bar.

A bellows not only protects the operator, but also the scissor mechanics and hydraulic cylinders from environmental influences and dirt. A bellows can also be retrofitted, but the space required must be checked by the customer - our technicians will be happy to advise on this.

Lift table with turntable

If it is not enough to just lift your goods or product up and down, our turntables are used. These rotating platforms can be set up on almost all lifting table models and make it possible to manually rotate the product through 360°. The round rotating platform is shown here, which does not protrude beyond the actual platform, so the lifting table can be raised or lowered in any rotating position. With the square rotating platforms, the lifting table only lifts if the two platforms are congruent.

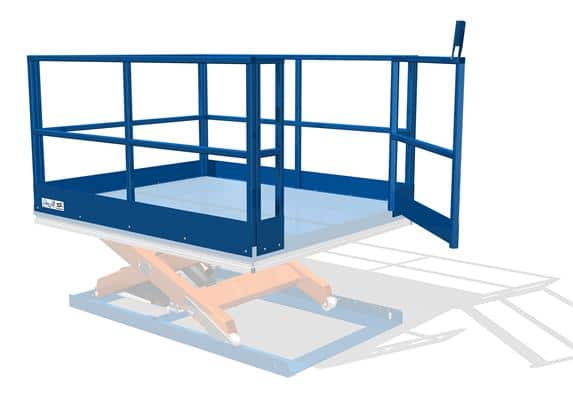

railings and gates

Whenever lifting tables can be stepped on and the lift is more than 500mm, the platforms must be equipped with fall protection. We always use our stable railings and gates here. These can be welded, screwed or pluggable. If a manual security from the gate is not sufficient, we can also equip it with an electronic contact. Lengths and shapes of the railing on the lifting table can be individually adjusted.

Almost all lifting table models can be equipped with our accessories:

- Wheel base under the base frame, the lifting table can therefore be moved and is not tied to a work location.

- Lift table with battery operation or UPS.

- Lift truck device under the base frame, so you can move the lift table with a classic lift truck, pedestrian stacker or forklift.

- Platform cover plate with tear plate as anti-slip protection. Used for lifting tables that can be entered.

- Limit switch or stroke limit switch for setting the upper stroke position. This accessory is used if the lifting table should always stop at the same position at the upper stop.

- Tailgates for easy loading and unloading of flatbed trucks or trucks. Available manually or hydraulically. Loading flaps are used to bridge the gap between the vehicle and the lifting table .

- Attachment bolts for the lower stop, which ensure that the scissors are relieved when loading and increase their service life. These mechanical supports can also be adjusted in height or ordered with rubber buffers to reduce noise.

- Railings and gates on the platform as fall protection. The pallet or goods are placed on the lifting table in the extended state, so that they cannot fall down, this accessory is selected.

- Special controls such as B. foot switch, radio remote control, key switch or wired to a terminal strip for customer control.

- Lifting eyes for easier assembly and convenient transport. The round eyelets are screwed through the platform into the base frame, so you can easily transport the lifting table with a crane or forklift and lift it into the pit.

- Round and square turntables, which are built on the lifting table platform. With these rotating platforms you can turn your lattice box or pallet into a comfortable working position.

- Rail carriages are used when the lifting table has to be moved along a straight line.

- Extendable lifting table platforms are mostly used with aerial work platforms so that employees can get to the work site more easily.

- Reinforced platforms for traversing scissor lift tables in the lower lift position. With this design, even articulated lorries can drive over the lifting table without it bending.

- Protective grid or grid shirt as underflow protection under the lifting table platform is possible on all 4 sides.

- PVC roller blind, protective curtain, carpet or curtain under the lift table platform.

- Bellows as protection against dirt all around under the lifting table platform.

- Roll-off safety devices, mechanical or hydraulic, ensure that transport equipment does not roll off the platform.

- Bolt locking against deflection when loading at the upper stop. We mainly use this mechanical locking mechanism for lift tables that connect two floors.

- Scales integrated in the lifting table base frame, so you can not only lift your goods, but also always have an eye on the weight.

- Ramps are used on flat lift tables so that you can place the pallet on the platform with a lift truck.

Other accessories

If you have any questions, please contact us immediately Contact on. We are happy!