LIFT TABLE

INFO PORTAL

Extensive information portal on the topic of lifting tables

All possible lifting table variations

are presented here!

Maluk.at offers lifting tables for almost all work areas and industries. Whether in mechanical engineering, the wood industry, the food and pharmaceuticals industry, in front of loading ramps or in conveyor systems, we always have the right solution.

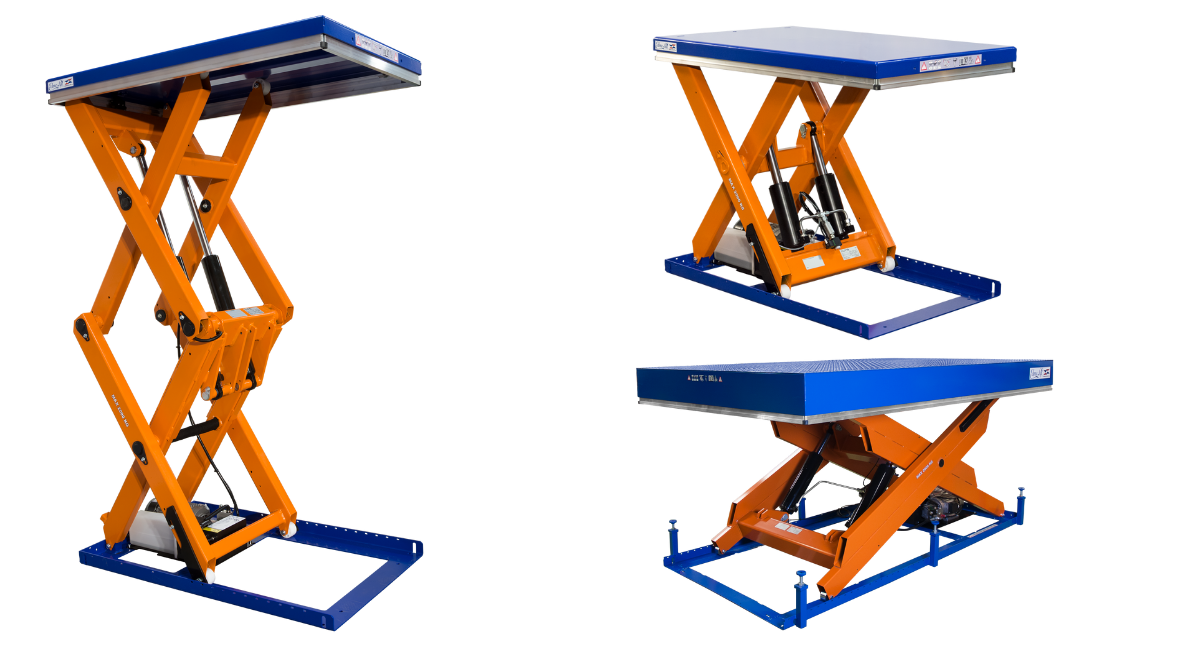

Our small tables start with a load capacity of 50 kg and are built into furniture. The large scissor lifts start at 200 kg and reach a standard load capacity of 10,000 kg and are ideal for moving objects. There are currently over 300 types of standard products in the lifting table delivery program.

We also know that every customer is different and therefore offer tailored and flexible solutions to your specific needs. No matter what requirements you have for our lifting tables, we will find the right lifting table solution and will be happy to create your personal offer for you.

Maluk, a Carinthian company with over 15 years of experience, offers a wide range of lifting tables. These include standard scissor lift tables, flat lift tables, loading lift tables, dock lift tables and special or special lift tables for special requirements.

Best lift table information

The lifting table is our passion

A lifting table, often called a scissor lift table, is generally used to lift bulky and heavy weights over relatively short distances. Common applications include lifting pallets, loading motor vehicles and performing positioning work.

No matter the size of your business, you can count on Maluk's experienced professionals. By purchasing our safe, productive lift table products, you can save yourself the strenuous daily lifting.

TOP prices

We have been selling lifting tables and much more at fair prices for decades!

Quality

We rely on the good & proven European machine quality.

service

Best advice through years of experience. Of course for free!

special dimensions

Tell us what you need. We have the right lifting table!

A suitable lift table for all challenges

Our lifting tables

Column lifter with grid shaft

Column lift with grid shaft Hydraulic column lift with grid shaft in an industrial plant. Our Czech industrial customer came to us with the challenge of transporting his goods

Lift Table Information

Lift Tables are essential tools for lifting small or large loads. lifting tables They can be found in many industries, including manufacturing and construction. A lift table is useful for reducing the risk of musculoskeletal problems and increasing safety and productivity. There are several types including electric, hydraulic and pneumatic. They are available in different sizes and can carry up to 100 tons. You are welcome to browse our website for more information about each type and their characteristics.

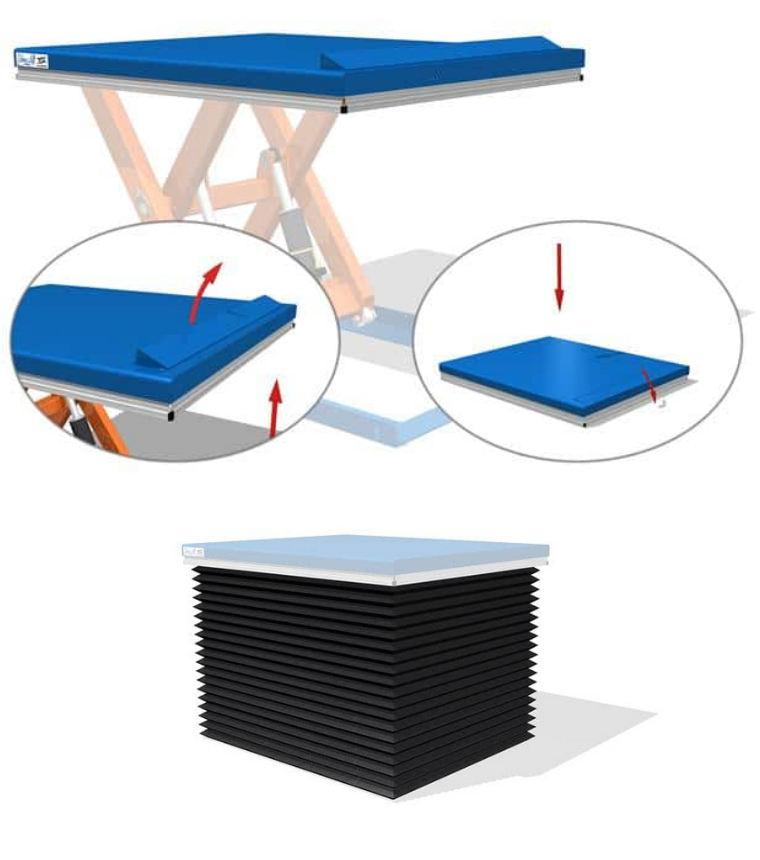

There are two kinds: an electric and a manual scissor lift table. They are available in various sizes and designs from 50 to 2000 cm platform length. Choose the model that suits your specific needs and budget. Our scissor lift tables are versatile and can be used for a variety of jobs.

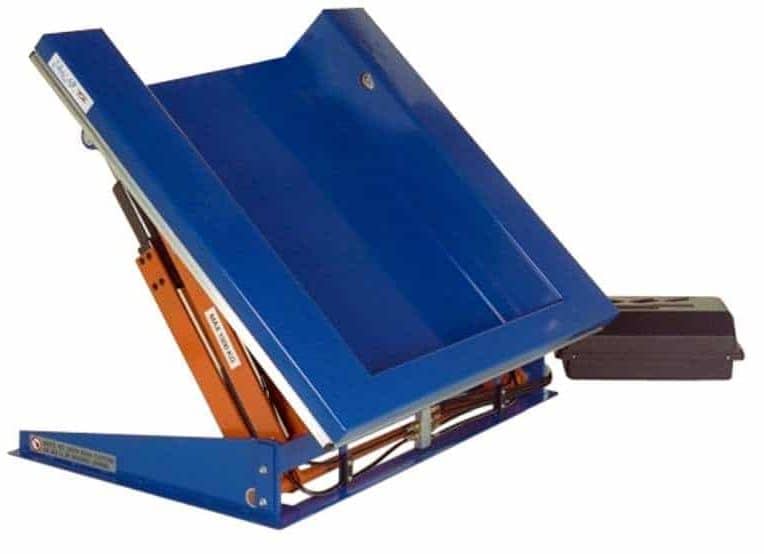

A tilting lift table can also be ordered. The lifting tilting devices are available in standard and special versions, tilting lifting tables are manufactured upon customer request. Depending on the application, we can offer a wide range of accessories. To do this, tell us which goods need to be tipped. Depending on your needs, you can choose between countless different load capacities. A heavy-duty lift table, often called a scissor lift table, can generally lift up to 100 tons and is well suited for manufacturing and industrial environments. Depending on the application and load distribution, our technicians select the appropriate lifting table, manufactured by Columbus McKinnon.

Our tandem scissor lift tables can be used for large and long loads. You can continuously adjust the height of your work surface. This type of lifting table is ideal for lifting heavy objects in the wood industry or in plant construction and conveyor technology. Depending on the requirements, roller conveyors or chain conveyors can also be set up. It is always important that we know the load distribution and the application.

Scissor lift tables are all-rounders

Of all the types, hydraulic scissor lift tables are among the most popular and affordable. They are suitable for a wide range of industrial applications and are manufactured safely and in accordance with standards. The best scissor lift tables are made from the highest quality materials using the most advanced equipment. Therefore, they are ideal for a wide range of applications. You can use them in factories, warehouses and production halls for many purposes.

Maluk GmbH offers a comprehensive range of scissor lift tables for various industrial and commercial environments. The scissor lift tables can be used for industrial, commercial and private purposes. They are safe and reliable and are CE marked. These qualities make them an essential part of many jobs.

Scissor lift tables come in many sizes and shapes and are used in many areas such as industry, but also in hotels, schools and public buildings. They can be used by both skilled workers and laypersons. They can be used to lift objects from different heights, providing maximum flexibility for your work. Depending on the size of the scissor lift table, you can choose the design and load capacity that best suits your needs.

Maluk is a great place to buy scissor lift tables. Our company offers a large inventory of lift tables for industrial, commercial and residential use. They are reliable and easy to use. These tables are made with quality materials and state-of-the-art equipment to ensure safety and durability.

A lifting table makes daily work easier

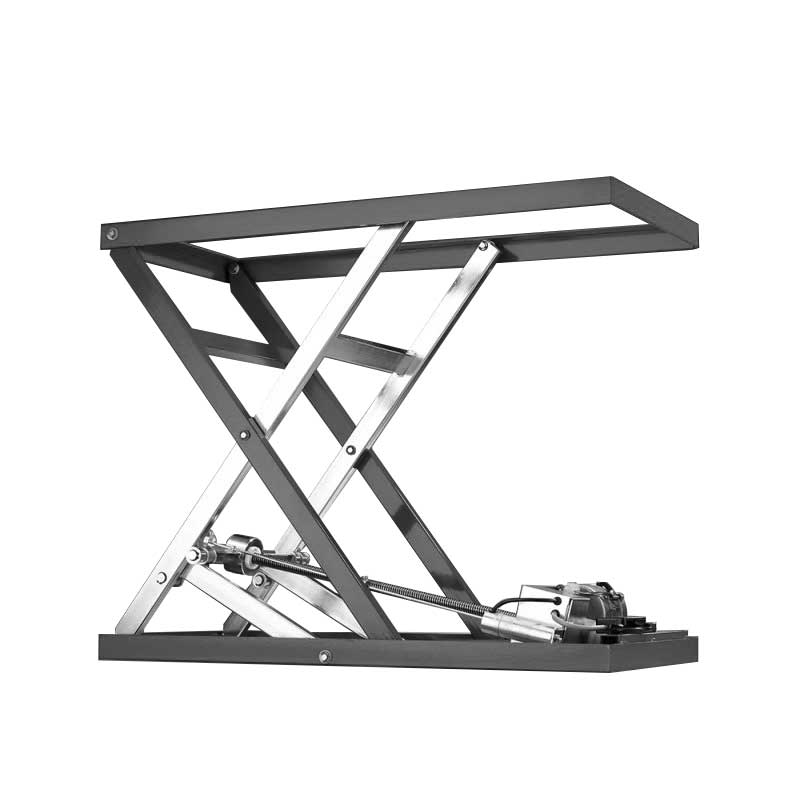

What are lift tables and how do they work? What are lift tables and how do they work? These lifters are constructed with scissor legs connected to a platform and base frame. When these scissors open, the platform rises vertically. There are several variations of scissor designs used to raise and lower the platform. Here we give a brief explanation of which scissor lift tables are available and how these workstation systems make everyday work easier.

Industrial operations typically require lifting heavy loads, and a lift table helps employees do this more safely. They allow employees to lift and move heavy objects without straining their backs or muscles. They are ergonomically designed to reduce stress and make employees more productive. Lift tables simplify everyday tasks and increase productivity in a wide range of applications.

scissor lift table

A scissor lift is an indispensable tool for heavy lifting, production and maintenance work. Its ease of use helps employees lift heavy objects to an ergonomic height without endangering their health and safety. Scissor lift tables are incredibly versatile and can be used for a variety of tasks.

Scissor lift tables are a popular gift for any workplace because of their versatility and affordability. The manual lift tables do not require electricity and can be used for long periods without downtime. Depending on the workplace, you can choose between a standard lifting table or a custom-made model. A scissor lift table is available in many designs and materials.

A scissor lift table can vary widely in quality and construction, but all follow a basic design. They can be customized to perform specific tasks. Hydraulic scissor lift tables can be adjusted to better position loads or be more ergonomically aligned in a specific area. The platform of a scissor lift table can also be adapted to suit all requirements.

Advantages of lifting tables

Lift tables can reduce the risk of musculoskeletal injuries by eliminating the need to manually lift heavy loads. According to the Bureau of Labor Statistics, there were 365,580 cases of musculoskeletal disorders in 2014. That's 33.8 incidents per 10,000 employees. As a result, injured workers are absent from sick leave. This subsequently leads to increased costs and possibly delayed deliveries. Protect your employees and support their work with scissor lift tables.

Lifting tables, also known as lifting tables, have many advantages: not only can they carry large amounts of weight, but they are also adjustable in height and inclination. This new work perspective can increase accuracy in cutting and welding. Some of the features listed below make them the ideal option for efficiency in production. These are just a few of the many benefits that a lift table can offer.

Ergonomic design: Aside from the ergonomics, a lift table also helps employees to be more aware of their posture. Getting up every hour strengthens your core and back muscles, which helps you stay awake and avoid strain throughout the day. It will also improve your overall performance. In addition to reducing the risk of back pain and muscle injuries, lifting tables can also reduce the risk of absenteeism and presenteeism, two important aspects of business life.

Lift tables not only increase productivity and accuracy, but also reduce the risk of back, muscle and joint pain. They can be used for many tasks such as quality control, machine tending, repair, quality control, inspection and line tending. They are also easy to handle and therefore pose no risk to workers.

Lift table types

There are many types of lift tables. They can be classified by their power source or lifting mechanism. Manual lift tables are the most basic type of lift tables and are commonly used for light-duty applications. They make work easier for workers and make them safer. Manual lifting tables are often operated with a crank or a foot pedal. Electric lifting tables lift at the push of a button. The power can be supplied by a rechargeable battery or a direct power connection.

Whether you choose manual or electric powered lift tables, you will be satisfied with their efficiency and durability.

Electric mobile lifting tables

Electromobile lifting tables are a perfect way to make everyday work easier. They can lift heavier loads than a human and can be used to speed up production. They are much more user-friendly than manual ones. In addition, they do not slow down the operators and are therefore a good option for every workplace.

Hydraulic lifting tables Designed for heavy-duty applications, they can raise and lower heavy objects to an optimal height for efficient work. The adjustable height of these workstations minimizes the risk of repetitive motion injuries and physical strain.

A key feature of electric lift tables is the battery drive. Alternatively, you could also do this with a power plug, but this means that you always have to carry it with you and plug it in. To prevent accidental falling, they can be equipped with safety technology. They can also be fitted with a turntable so that the goods can be rotated for easy access from all sides.

Special designs are also possible for the mobile electric lifting table trolley. There are hardly any limits to customer wishes.

ATEX zone classification of lift tables / EX lift table

The ATEX zone classification for lift tables is the most important thing when choosing a lift table for hazardous environments. This classification is used in industries where explosive atmospheres are present, such as those found in chemical plants and petrochemical plants. In such environments, combustible gases, combustible dust and particles can combine and form an explosive atmosphere. Equipment used in such situations should be explosion-proof and non-sparking.

There are different zones for electrical equipment, e.g. B. for potentially explosive environments. These zones determine the safe use and commissioning of various types of electrical devices, such as: B. lifting tables. A lift table classified as an ATEX zone is suitable for installations in a zone classified according to the type of gases and dusts contained. The Maluk range includes lifting tables for various ATEX zones. To ensure compliance with safety regulations and to facilitate commissioning, the tables are supplied with extensive documentation and operating instructions. The unit and the control are installed outside the EX zone.

The ATEX zone classification of lift tables can make daily work in potentially explosive environments easier. Lift tables designed according to their ATEX zone classification are approved for use in ATEX areas.

Satisfied Maluk customers

Customer testimonials about our lifting tables

Our company is enthusiastic about Maluk. The lifting tables are of the highest quality. The prices are ok too

Arthur Probst

The Maluk lift tables are very good value for money. We are very satisfied!

Sandra Peternell

I like the service and the quick response times. I would happily recommend Maluk.

Sasha Cerne

The workers in our machine park are enthusiastic about the lifting tables. Very good quality!

Thomas Koller

Maluk is a Carinthian quality company

Become a satisfied Maluk lifting table customer!

A comprehensive guide to lift tables

lifting tables Lift tables are important devices in industrial, commercial and residential settings. They are indispensable for a wide range of applications and help to improve efficiency and productivity. In this article, we will discuss in depth the different aspects of lift tables, from their function and importance to the different types and uses in different industries.

What are lift tables and how do they work?

Lift tables are devices used to raise loads to a specific height. They are constructed with scissor legs connected to a platform and base frame. When the scissors open, the platform rises vertically. There are several variations of scissor designs used to raise and lower the platform.

They provide an efficient solution for lifting and lowering heavy loads, making them an essential tool in many industrial and commercial settings.

The importance of lift tables

Lift tables play a crucial role in many industrial and commercial settings. They allow employees to lift and move heavy objects without straining their backs or muscles. They are ergonomically designed to reduce stress and make employees more productive. Lift tables simplify everyday tasks and increase productivity in a wide range of applications.

“Lift tables are an essential part of our production line. Not only have they increased efficiency, but they have also reduced the risk of workplace accidents. Maluk helped us with this.” – Production manager of a large manufacturing company.

Different types of lift tables

There are different types of lift tables that are suitable for different applications. Below are some of the most common types, including the hydraulic lift table and the electric lift table.

1. Hydraulic lifting tables

This type of lift table uses a hydraulic system to raise and lower the platform. They are very powerful and can handle heavy loads with ease. Hydraulic lift tables are available in a variety of sizes and lifting capacities and can be used in both industrial and commercial settings.

2. Electric lift tables

Electric lift tables use an electric motor that drives a spindle to raise and lower the platform. They are easy to operate and offer precise lift height control. Electric lift tables or screw jack tables are ideal for applications that require high accuracy and control.

3. Manual lifting tables

Manual lift tables, powered by hand or foot pumps, are ideal for smaller tasks and environments where electricity is not available. They are inexpensive and easy to use, but require more physical effort than their hydraulic or electric counterparts. This type of lifting table is often operated with a hand lever.

Choosing the right lift table

Selecting the right lift table depends on a number of factors including the type of application, the load being lifted and the specific needs of the job. Here are some factors to consider when choosing a lift table.

- Load capacity: The load capacity is a key factor when choosing a lift table. You must choose a lift table that is capable of safely supporting the maximum load you intend to lift.

- Lift height: Lift height refers to the maximum distance the lift table can lift. It should be selected based on the specific needs of your application.

- Platform size: The size of the platform is another important factor. It should be big enough to safely carry the load, but not so big that it takes up too much space.

- Type of application: The type of application can also influence the choice of lift table. For example, manual lift tables are ideal for smaller tasks and environments where power is not available, while electric or hydraulic lift tables are better suited for larger, power-hungry applications.

- Price: Finally, price should also be considered when choosing a lift table. It's important to choose a lift table that is within your budget, but remember that the cheapest option isn't always the best. It's often better to spend a little more for a quality product that is durable and reliable.

Use of lifting tables in various industries

Lift tables are used in a variety of industries including:

- Production and Manufacturing: In manufacturing and manufacturing environments, lift tables are commonly used to lift heavy machinery, equipment, or materials. They allow workers to access these items in a convenient and safe way.

- Warehousing and Logistics: Lift tables are often used in warehouses and logistics centers to lift and move pallets and other heavy goods. They can also serve as adjustable work platforms for workers.

- construction industry: Lift tables are often used on construction sites to lift and move heavy building materials. They can also serve as adjustable platforms for workers working at height.

- Healthcare: Lift tables are often used in healthcare facilities to safely and conveniently lift and move patients. They can also serve as adjustable beds or examination tables.

Safety when using lifting tables

Operational safety is a central aspect when using lifting tables. It is important to ensure the lift table is properly maintained and operated to avoid accidents and injuries. Here are some safety tips for using lift tables:

- Ensure that the lift table is properly installed and maintained. Regular inspections and maintenance can help identify and fix potential problems early.

- Train employees to safely operate the lift table. They should know how to operate the lift table correctly and what safety precautions they need to take.

- Loads should always be securely placed and secured on the lift table. Insufficiently secured loads can fall and cause injury.

- Make sure the area around the lift table is clear of obstructions. This can help prevent accidents and injuries from falling objects.

Lift tables are indispensable devices in many industrial and commercial environments. They provide an efficient and safe solution for lifting and lowering heavy loads, helping to improve efficiency and productivity. It is important to choose the right lift table for your specific needs and ensure it is properly maintained and operated to ensure safety and longevity.