Transporting loads to the upper floor

The Austrian customer has a huge warehouse and had to expand it. The upper floor was opened up for this purpose. The challenge was that a deep pit could not be created at the lower stop, i.e. on the ground floor. Unfortunately, the solution with a hydraulic scissor lift table is not possible this time.

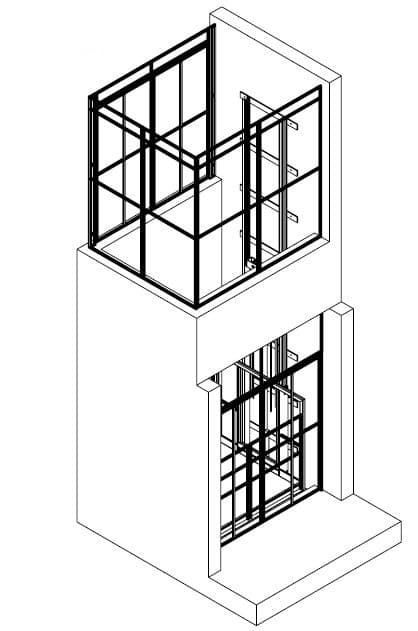

We then decided together with the customer to use a hydraulic column jack. This has the advantage that the pit only has to be 100mm deep. To do this, the screed was simply removed. The disadvantage is that some space is required on the side for the column, but this was relatively easy to do since the shaft was newly built anyway.

The column lifter has a load capacity of 1000 kg and a platform of 2000 x 1400 mm. The difference in level is 3700 mm and can be easily bridged with the load lifter.

Details of the column jack for transporting goods

Planning of the goods lift

The customer told us the necessary dimensions and then asked us to make a plan. We drew the load lifter, including the surrounding shaft, and sent it to the customer for inspection. After a few changes, we developed the perfect solution for the customer, approved it in the factory and then produced it.

We never start production without approving our drawing. For systems that are tailored precisely to the customer, it is very important to clarify all the details in advance.

Take measurements on site

It often happens that customers want to be on the safe side and ask us to measure the shaft again on the construction site. The shaft is usually built by the construction company according to our specifications and then checked by the customer or the construction company. An additional measurement from us is not necessary. For this project, the customer ordered and of course received a measurement from our technicians.

Column jack at the lower stop

We installed a two-leaf revolving door at the lower stop. This is particularly high because the customer often has to transport very tall goods.

The door is equipped with a forced contact. This monitors whether the door is closed properly and then gives the release to the control.

Using the yellow button on the wall, the employee can send the goods to the upper floor.

Upper stop from the freight lift with a grid shaft

The customer's concrete shaft was built on the first floor only on one side all the way up. That's why we closed the other sides with our mesh shaft so that no one can support people down.

We also installed a gate on one side, which is also connected to the control. Gate only opens when the platform is parked properly.

Order lifting tables now

If you have any questions, please contact us immediately Contact on. We are happy!