Loading lifting table with assembly

We had to have one for a large German grocer massive and robust loading lifting table delivery and on site mount. After assembly, we carried out training and had the acceptance carried out by an authorized civil engineer.

Due to the use indoors, we decided to paint it. We used galvanized loading lifting tables outside.

Assembly process for the loading lifting table

Base frame for the pit

Lifting from the loading lifting table

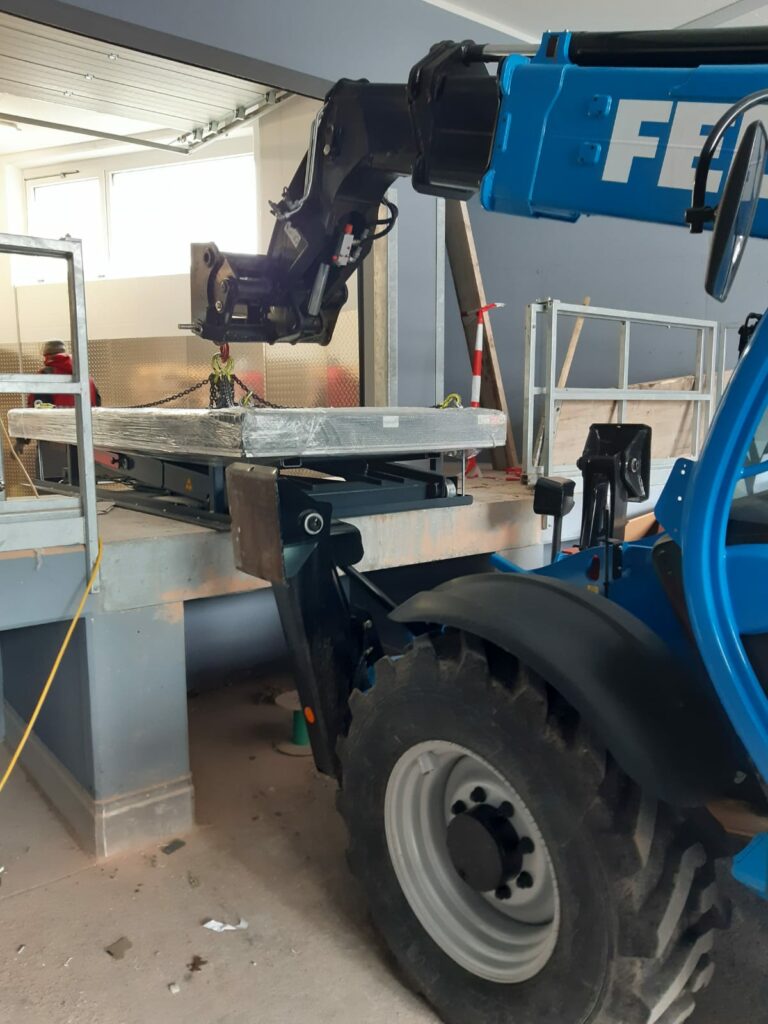

The Lifting from a lifting table is usually carried out directly with a crane truck, a forklift or the construction crane. Every now and then, however, special challenges arise due to construction progress or structural conditions.

The installation here was very difficult because there was a concrete ramp on the outside with an approximately 3 meter long platform. The massive one had to be behind it loading lift table, which has a dead weight of 2500kg, must be lifted into an even deeper pit.

In addition, the clearance height of the gate was very low and a classic truck loading crane would not have been able to do it.

So we resorted to a telescopic loader. This was able to lift the loading lifting table into the building with the narrow side first. Inside we had to go over the pit to get to it lifting table hanging from the crane.

s

Loading lifting table with lifting eyes

Commissioning of the loading lifting table

Order lifting tables now

If you have any questions, please contact us immediately Contact on. We are happy!