Special design loading lifting table

Loading lifting tables from maluk are used to load or unload a truck, semi-trailer or flatbed truck.

The truck drives onto the company premises and parks in front of it lifting table. The loading lifting table lifts to the level of the loading area. The truck driver or warehouse employee folds the loading flap into the truck and unloading with a pallet truck onto the lifting table can begin.

If the goods are on lifting table is lowered to the desired level and transported to the warehouse.

If the goods are on lifting table is lowered to the desired level and transported to the warehouse.

Loading lift tables are available in all sizes with all load capacities. Common platform dimensions are 2500 x 2000 mm or 3000 x 2000 mm. The load capacity varies from 2000 kg, 4000 kg to 6000 kg.

Lift tables for truck loading are usually located outdoors, which is why they are often galvanized. In this case, the motor and controller should be placed outside the pit.

Stable loading lifting table according to customer requirements

Planning of the loading lifting table

In order to be able to create an offer, information about the platform size, the stroke, the load capacity and the application is sufficient.

Once the order is placed, the designer creates a system drawing with all dimensions and options. Depending on the scope of the order, a technician will also travel to the construction site to check the natural dimensions.

If the Loading lifting table into a pit of course, we create a pit plan with all the necessary information such as empty pipes, edge protection, drain, ...

We would be happy to create one too Drawing of the loading lifting table in 3D, so that even if you are not an experienced lift table professional, you can see all the details perfectly.

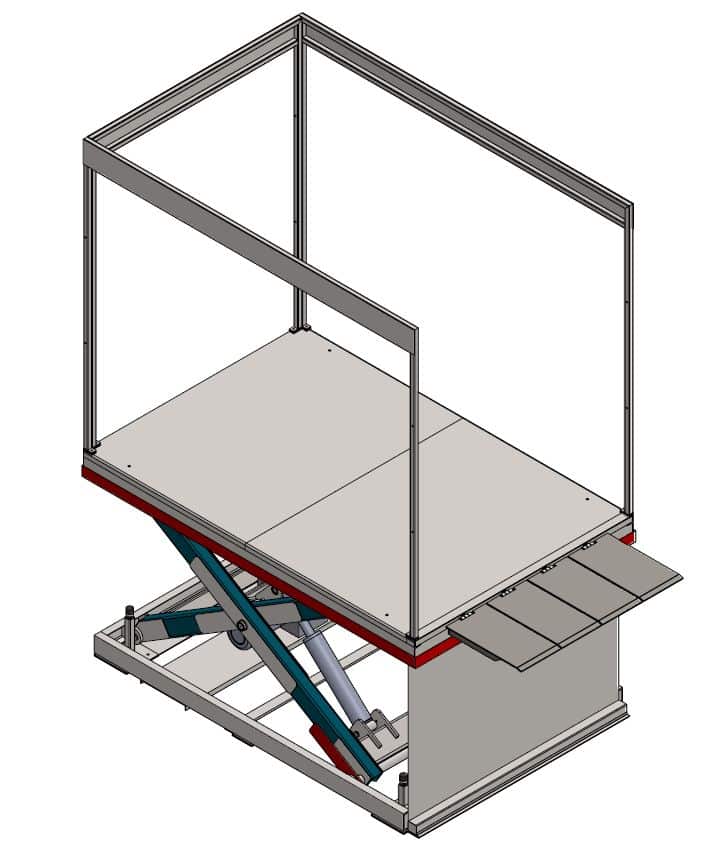

Portal as fall protection

For this project, the Austrian customer ordered two identical loading lift tables. We screwed a portal onto three sides of the platform of the truck lifting table.

The lifting tables were placed in a recess closed on three sides on one side of the hall. If the lifting table is in the lower position, this would create a fall onto the platform. Through the portal, the warehouse employee sees that the platform is at the bottom and he has to be careful.

Lt. According to the lifting table standard EN1570-1, fall protection must be installed in front of lifting systems from a level difference of 500 mm.

A mobile portal is sufficient up to a height of 1600mm. Above this you have to install a permanently installed gate at the top stop.

A mobile portal is sufficient up to a height of 1600mm. Above this you have to install a permanently installed gate at the top stop.

Loading lift table with roller blind

As described above, the lifting table stands on 3 sides against a concrete wall. However, the fourth side, towards the truck or the courtyard level, is freely accessible. To ensure that neither people nor dirt get under the platform, this side was secured with a pull-out PVC protective roller blind under the platform.

This underflow protection is used as an alternative to protective grilles or bellows.

The Platform surface was with one Tear plate manufactured. As soon as people can enter the platform during loading, this is Lt. Standard required – risk of slipping.

The loading flaps are placed manually in the truck by the operator so that a pallet truck or trolley can be driven between the lifting table and the truck.

The loading flaps are placed manually in the truck by the operator so that a pallet truck or trolley can be driven between the lifting table and the truck.

An inspection hatch was also installed in the platform, as the motor and the controls are located on these two Loading lift tables located under the platform.

In red, next to the scissors, you can see the maintenance support. You have to insert this if you are under the for maintenance purposes loading lift table must rise. This mechanically prevents the lifting table from sinking.

Order lifting tables now

If you have any questions, please contact us immediately Contact on. We are happy!