Lifting table with built-up loading bridge

The load capacity is 6000 kg. The platform is 3000mm long and 2250mm wide. The lifting table alone has a height of 500mm, together with the feed ramp it is 1350mm. The level difference is 1300mm.

Project details of the lifting table with loading ramp

Loading bridge mounted on lifting table

Before we deliver our lifting systems, they are connected in the factory and tested over coffee J. A test is also carried out using load weights and all functions are activated several times.

On the classic ones A Hörmann loading bridge was set up on a scissor lift table. We then assembled this entire system at the customer's site.

Lift table with loading bridge delivered ready for assembly

The one tested at the factory Lift table with loading bridge is transported to the customer in a semi-trailer ready for connection. The customer provided a crane truck with a driver for the assembly.

The lifting table with feed ramp is lifted with the crane into the pit prepared by the customer, aligned and then screwed together. The cabling then begins through the prepared empty conduits up to the installation position of the control and the unit.

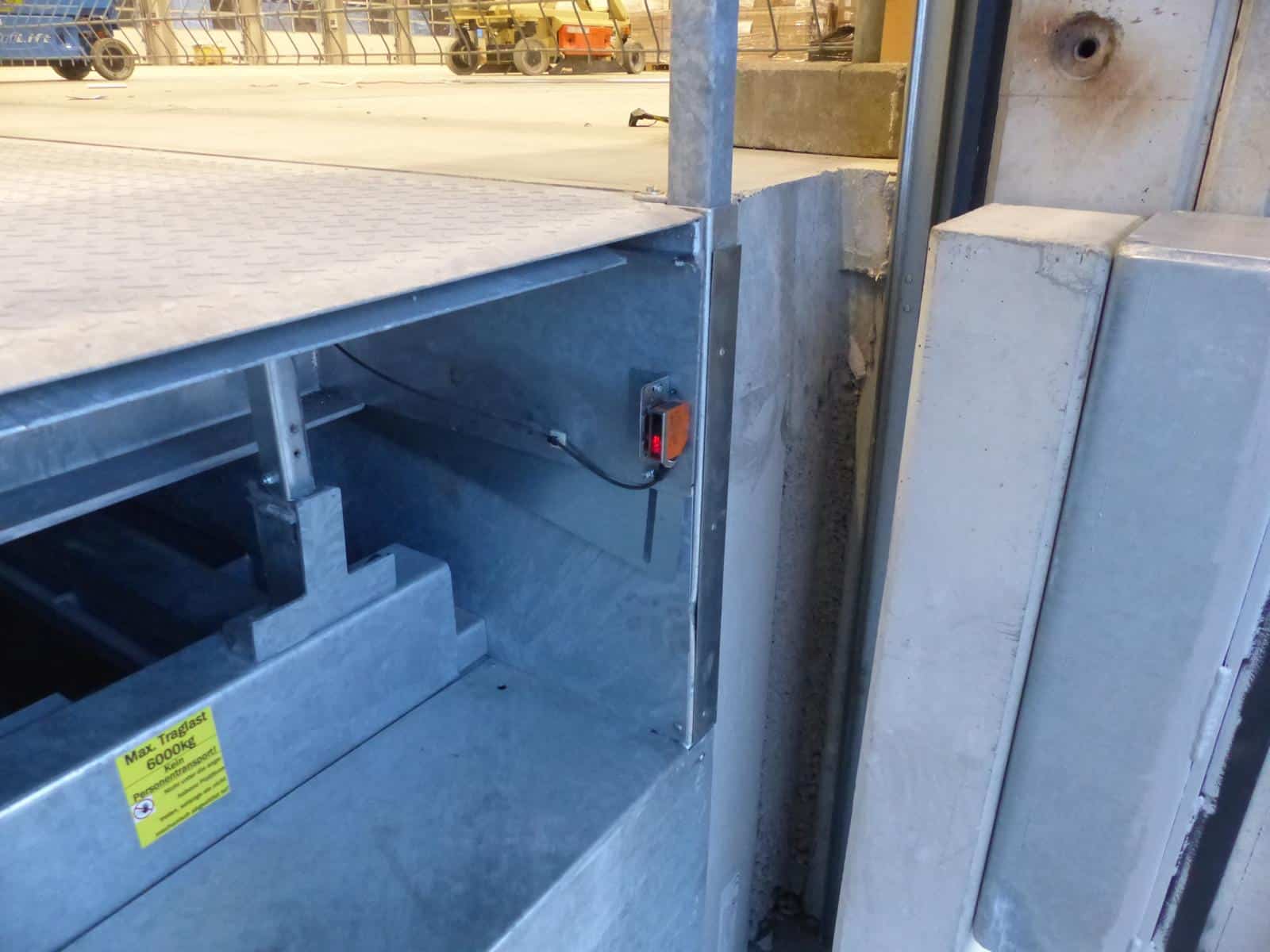

Light barrier under the loading bridge

As an additional safety device, we have installed a light barrier under the loading bridge, which is built on the lifting table.

This light barrier has the task of stopping the entire system if there is an obstacle under the loading ramp. This is particularly important when lowering to street level so that no one can become trapped or goods can be damaged.

Mobile portal on the loading lifting table

As soon as the Lift table including loading bridge has lowered to street level, there is a risk of falling from the hall onto the lifting system.

To avoid having to install a railing and gate at the upper stop, we built a mobile portal on the platform as fall protection. This protrudes 1100mm beyond the upper stop if the lifting table with ramp is at the lower stop.

During assembly, the fitters also check that there are no shearing or crushing points between the portal and the customer's installations, such as the gate.

Order lifting tables now

If you have any questions, please contact us immediately Contact on. We are happy!