HUBTISCH

INFO-PORTAL

Umfangreiches Informationsportal zum Thema Hubtische.

Alle möglichen Hubtisch Variationen

werden hier vorgestellt!

Maluk.at bietet Hubtische für nahezu alle Arbeitsbereiche und Branchen an. Egal, ob im Maschinenbau, der Holzindustrie, der Lebensmittel- und Pharmaindustrie, vor Laderampen oder in Förderanlagen, wir haben immer die passende Lösung.

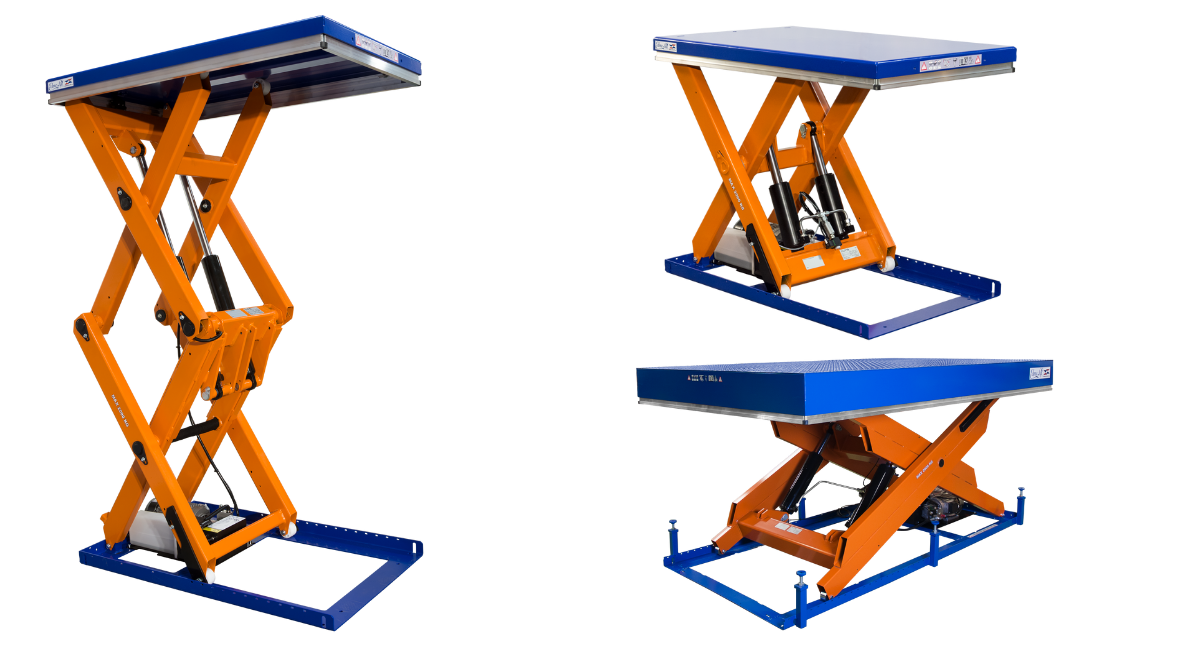

Unsere kleinen Hubtische beginnen bereits bei einer Tragkraft von 50 kg und werden in Möbeln eingebaut. Die großen Scherenhebebühnen, auch Scherenhubtisch genannt, beginnen bei 200 kg und erreichen im Standard eine Tragkraft von 10.000 kg und eignen sich ideal für das Bewegen von Gegenständen. Aktuell gibt es über 300 Typen von Standardprodukten im Hubtischlieferprogramm.

Wir wissen auch, dass jeder Kunde anders ist und bieten daher maßgeschneiderte und flexible Lösungen für Ihre spezifischen Bedürfnisse an. Egal, welche Anforderung Sie an unsere Hubtische haben, wir finden die passende Hubtisch-Lösung und erstellen Ihnen gerne Ihr persönliches Angebot.

Maluk, ein Kärntner Unternehmen mit über 15 Jahren Erfahrung, bietet ein breites Hubtisch-Sortiment an. Dazu gehören Standard-Scherenhubtische, Flachhubtische, Verladehubtische, Dockhubtische und Sonder- bzw. Spezialhubtische für besondere Anforderungen.

Beste Hubtisch Informationen

Der Hubtisch ist unsere Leidenschaft

Ein Hubtisch, oft auch Scherenhubtisch genannt, wird im Allgemeinen eingesetzt, um sperrige und schwere Gewichte über relativ kurze Entfernungen anzuheben. Zu den häufigen Anwendungen gehören das Heben von Paletten, das Beladen von Kraftfahrzeugen und die Durchführung von Positionierungsarbeiten.

Unabhängig von der Größe Ihres Unternehmens können Sie sich auf die erfahrenen Fachleute von Maluk verlassen. Durch den Kauf unserer sicheren, produktiven Hubtischprodukte können Sie sich das anstrengende tägliche Heben ersparen.

TOP Preise

Wir verkaufen seit Jahrzehnten Hubtische und vieles mehr zu fairen Preisen!

Qualität

Wir setzen auf die gute & bewährte europäische Maschinenqualität.

Service

Beste Beratung durch jahrelange Erfahrung. Natürlich kostenlos!

Sondermaße

Sagen Sie uns, was sie benötigen. Wir haben den passenden Hubtisch!

Ein passender Hubtisch für alle Herausforderungen

Unsere Hubtische

Säulenheber mit Gitterschacht

Säulenheber mit Gitterschacht Hydraulischer Säulenheber mit Gitterschacht in einem Industriebetrieb. Unser tschechischer Industriekunde ist mit der Herausforderung auf uns zu gekommen, dass er seine Waren

Hubtisch-Informationen

Lift Tables sind unverzichtbare Werkzeuge, um kleine oder große Lasten zu heben. Hubtische sind in vielen Branchen zu finden, darunter in der Fertigung und im Bauwesen. Ein Scherenhubtisch ist nützlich, um das Risiko von Muskel-Skelett-Problemen zu verringern und die Ergonomie, Sicherheit und Produktivität zu erhöhen. Es gibt verschiedene Arten, darunter elektrische, hydraulische und pneumatische. Sie sind in verschiedenen Größen erhältlich und können bis zu 100 Tonnen tragen. Sie können gerne unsere Website durchsuchen, um weitere Informationen zu den einzelnen Typen und ihren Eigenschaften zu erhalten.

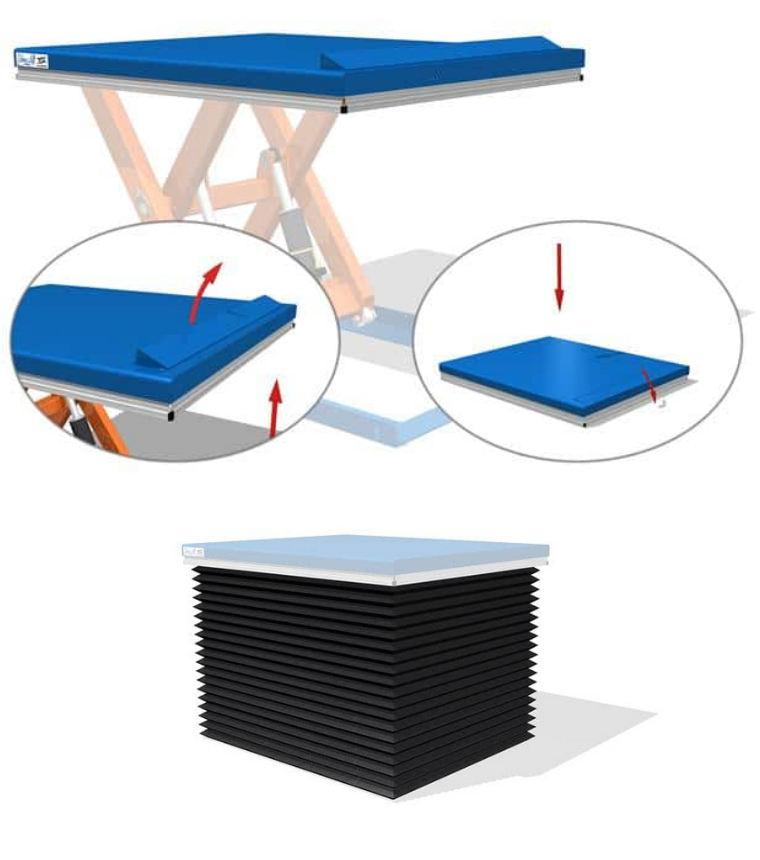

Es gibt zwei Arten: Wir bieten einen elektrischen und einen manuellen Scherenhubtisch. Sie sind in verschiedenen Größen und Ausführungen von 50 bis 2000 cm Plattformlänge erhältlich. Wählen Sie das Hubtisch-Modell, das Ihren spezifischen Anforderungen und Ihrem Budget entspricht. Unsere Scherenhubtische sind vielseitig und können für eine Vielzahl von Arbeiten verwendet werden.

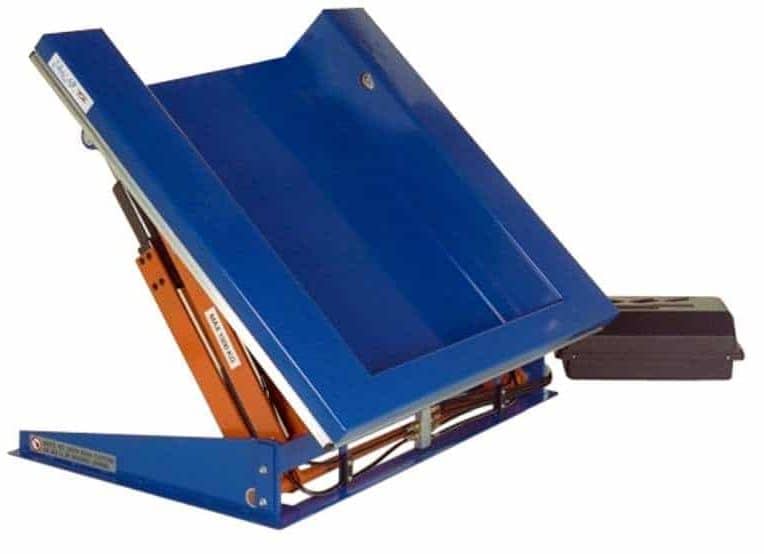

Ein Neige-Hubtisch kann ebenfalls bestellt werden. Die Hubneigegeräte gibt es in Standard- und Sonderausführung, Neigehubtische werden auf Kundenwunsch gefertigt. Je nach Anwendung können wir noch umfangreiches Zubehör anbieten. Hierzu teilen Sie uns mit, welche Ware gekippt werden muss. Je nach Bedarf können Sie zwischen unzähligen verschiedenen Traglasten wählen. Ein Schwerlast-Hubtisch, oft auch Scherenhubtisch genannt, kann im Allgemeinen bis zu 100 Tonnen heben und eignet sich gut für Produktions- und Industrieumgebungen. Je nach Anwendung und Lastverteilung wählen unsere Techniker den passenden Hubtisch aus.

Für große und lange Lasten können unsere Tandem-Scherenhubtische eingesetzt werden. Die Höhe Ihrer Arbeitsfläche können Sie stufenlos mit einem Hubtisch einstellen. Dieser Scherenhubtisch-Typ ist ideal zum Heben schwerer Gegenstände in der Holzindustrie oder im Anlagenbau und der Fördertechnik. Je nach Anforderung können auch Rollenbahnen oder Kettenförderer aufgebaut werden. Wichtig ist immer, dass wir die Lastverteilung und die Anwendung kennen.

Scherenhubtische sind Alleskönner

Hydraulische Scherenhubtische gehören unter allen Arten zu den beliebtesten und günstigsten. Hubtische eignen sich für eine Vielzahl von industriellen Anwendungen und werden sicher und normgerecht hergestellt. Die besten Scherenhubtische werden aus den hochwertigsten Materialien mit modernster Ausrüstung hergestellt. Daher sind sie ideal für ein breites Anwendungsspektrum. Sie können sie in Fabriken, Lagern und Produktionshallen für viele Zwecke verwenden.

Maluk GmbH bietet ein umfassendes Sortiment an Scherenhubtischen für verschiedene industrielle und kommerzielle Umgebungen. Die Scherenhubtische können sowohl für industrielle, gewerbliche als auch private Zwecke eingesetzt werden. Sie sind sicher und zuverlässig und mit einem CE-Kennzeichen versehen. Diese Eigenschaften machen den Hubtisch zu einem wesentlichen Bestandteil vieler Arbeitsplätze.

Scherenhubtische gibt es in vielen Größen und Formen. Hubtische werden in vielen Bereichen wie z.B. der Industrie, aber auch in Gastbetrieben, Schulen oder öffentlichen Gebäuden eingesetzt. Sie können sowohl von Facharbeitern als auch von Laien verwendet werden. Scherenhubtische können zum Heben von Gegenständen aus verschiedenen Höhen verwendet werden und bieten maximale Flexibilität für Ihre Arbeit. Abhängig von der Größe des Hubtisches können Sie die Ausführung und die Traglast wählen, die für Ihre Bedürfnisse am besten geeignet sind.

Maluk ist ein großartiger Betrieb, um Scherenhubtische zu kaufen. Unser Unternehmen bietet einen großen Hubtisch-Bestand für industrielle, gewerbliche und private Zwecke. Sie sind zuverlässig und einfach zu bedienen. Diese Scherenhubtische werden mit hochwertigen Materialien und modernster Ausstattung hergestellt, um Sicherheit und Langlebigkeit zu gewährleisten.

Ein Hubtisch erleichtert die tägliche Arbeit

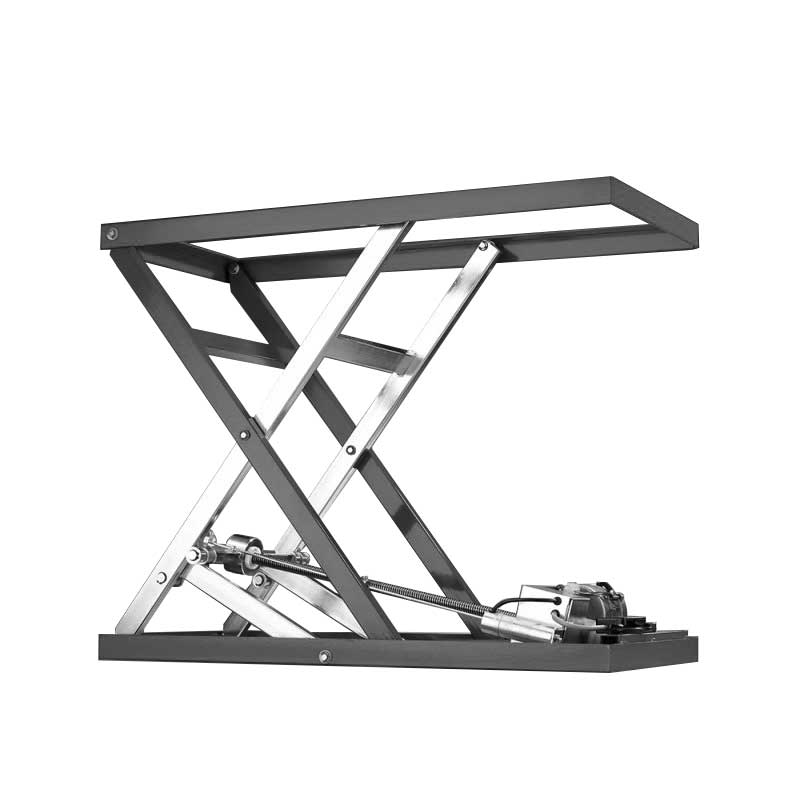

Was sind Hubtische und wie funktionieren sie? Diese Hebegeräte sind mit Scherenbeinen konstruiert, die mit einer Plattform und einem Grundrahmen verbunden sind. Wenn sich diese Scheren öffnen, steigt die Plattform vertikal an. Es gibt mehrere Variationen von Scherenkonstruktionen, welche verwendet werden, um die Plattform anzuheben und abzusenken. Hier geben wir eine kurze Erklärung, welche Scherenhubtische es gibt und wie diese Arbeitsplatzsysteme die tägliche Arbeit erleichtern.

Industriebetriebe erfordern typischerweise das Heben schwerer Lasten, und ein Hubtisch hilft den Mitarbeitern dabei, dies sicherer und ergonomischer zu tun. Sie ermöglichen es Mitarbeitern, schwere Gegenstände zu heben und zu bewegen, ohne ihren Rücken oder ihre Muskeln zu belasten. Sie sind ergonomisch gestaltet, um Stress abzubauen und die Mitarbeiter produktiver zu machen. Hubtische vereinfachen alltägliche Aufgaben und steigern die Produktivität in einer Vielzahl von Anwendungen.

Scheren-Hubtisch

Ein Scherenhubtisch ist ein unverzichtbares Werkzeug für schweres Heben, die Produktion und Wartungsarbeiten. Seine Benutzerfreundlichkeit hilft Mitarbeitern schwere Gegenstände auf eine ergonomische Höhe, ohne ihre Gesundheit und Sicherheit zu gefährden, anzuheben. Hubtische sind unglaublich vielseitig und können für eine Vielzahl von Aufgaben verwendet werden.

Scherenhubtische sind aufgrund ihrer Vielseitigkeit und Erschwinglichkeit ein beliebtes Geschenk für jeden Arbeitsplatz. Die manuellen Hubtische von Maluk benötigen keinen Strom und können über lange Zeiträume ohne Ausfallzeiten verwendet werden. Je nach Arbeitsplatz können Sie zwischen einem Standardhubtisch oder einem speziell angefertigten Modell wählen. Ein Scherenhubtisch ist in vielen Ausführungen und Materialien erhältlich.

Ein Scheren-Hubtisch kann in seiner Qualität und Konstruktion stark variieren, aber alle folgen einem grundlegenden Design. Sie können angepasst werden, um bestimmte Aufgaben auszuführen. Hydraulische Hubtische können angepasst werden, um Lasten besser zu positionieren oder in einem bestimmten Bereich ergonomischer ausgerichtet zu sein. Auch die Plattform eines Scherenhubtisches kann allen Wünschen entsprechend angepasst werden.

Vorteile von Hubtischen

Hub-Tische können das Risiko von Muskel-Skelett-Verletzungen verringern, indem sie das manuelle Heben schwerer Lasten überflüssig machen. Nach Angaben des Bureau of Labor Statistics gab es im Jahr 2014 365.580 Fälle von Muskel-Skelett-Erkrankungen. Das sind 33,8 Vorfälle pro 10.000 Mitarbeiter. Infolgedessen fehlen verletzte Arbeiter durch Krankenstand. Dies führt in weiterer Folge zu erhöhten Kosten und ggf. verspäteten Lieferungen. Schonen Sie Ihre Mitarbeiter und unterstützen Sie deren Arbeit mit ergonomischen Scheren-Hubtischen.

Hebetische, auch als Hubtische bekannt, haben viele Vorteile: Sie können nicht nur große Gewichtsmengen tragen, sondern sind auch in Höhe und Neigung verstellbar. Diese neue Arbeitsperspektive kann die Genauigkeit beim Schneiden und Schweißen erhöhen. Einige der unten aufgeführten Merkmale machen sie zur idealen Option für die Effizienz in der Produktion. Dies sind nur einige der vielen Vorteile, die ein Hubtisch bieten kann.

Ergonomisches Design: Abgesehen von der verbesserten Ergonomie hilft ein Hubtisch den Mitarbeitern auch dabei, ihre Körperhaltung besser wahrzunehmen. Stündliches Aufstehen stärkt die Rumpf- und Rückenmuskulatur, was ihnen hilft, wach zu bleiben und den ganzen Tag über Anspannungen zu vermeiden. Es wird auch Ihre Gesamtleistung verbessern. Neben der Reduzierung des Risikos von Rückenschmerzen und Muskelverletzungen können Hebetische auch das Risiko von Fehlzeiten und Präsentismus reduzieren, zwei wichtige Aspekte im Geschäftsleben.

Hub-Tische erhöhen nicht nur die Produktivität und Genauigkeit, sondern verringern durch ihre ergonomischen Eigenschaften auch das Risiko von Rücken-, Muskel- und Gelenkschmerzen. Sie können für viele Aufgaben wie Qualitätskontrolle, Maschinenbeschickung, Reparatur, Qualitätskontrolle, Inspektion und Bandbeschickung eingesetzt werden. Sie sind außerdem einfach zu handhaben und stellen daher kein Risiko für die Arbeiter dar.

Hubtisch-Arten

Es gibt viele Arten von Hubtischen. Sie können nach ihrer Energiequelle oder ihrem Hubmechanismus klassifiziert werden. Manuelle Hubtische sind die grundlegendste Art von Hubtischen und werden häufig für leichte Anwendungen verwendet. Sie erleichtern die Arbeit für Arbeiter und machen sie sicherer. Manuelle Hub-Tische werden oft mit einer Kurbel oder einem Fußpedal betrieben. Elektrische Hubtische, auch als Hubtisch elektrisch bekannt, heben auf Knopfdruck. Die Energieversorgung kann durch einen Akku oder einen direkten Stromanschluss erfolgen.

Egal, ob Sie sich für manuelle oder elektrisch angetriebene Hubtische entscheiden, Sie werden mit ihrer Effizienz und Langlebigkeit zufrieden sein.

Elektrische mobile Hub-Tische

Elektromobile Hubtische sind eine perfekte Möglichkeit, den Arbeitsalltag zu erleichtern. Sie können schwerere Lasten heben als ein Mensch und können zur Beschleunigung der Produktion eingesetzt werden. Sie sind viel benutzerfreundlicher als manuelle. Zudem bremsen sie die Bediener nicht aus und sind daher eine gute Option für jeden Arbeitsplatz.

Hydraulische Hubtische wurden für Schwerlastanwendungen entwickelt und können schwere Gegenstände auf eine optimale Höhe für effizientes Arbeiten anheben und absenken. Die einstellbare Höhe dieser Arbeitsstationen minimiert das Risiko von Verletzungen durch wiederholte Bewegungen und körperlicher Belastung.

Ein wesentliches Merkmal von elektrischen Hubtischen, auch als Hubtisch elektrisch bekannt, ist der Batterieantrieb. Alternativ könnte man diese auch mit einem Stromstecker ausführen, was aber dazu führt, dann man diesen immer mitführen und anstecken muss. Um ein versehentliches Herunterfallen zu verhindern, können sie mit Sicherheitstechnik ausgestattet werden. Sie können auch mit einem Drehteller ausgestattet werden, sodass die Ware gedreht werden kann, um sie von allen Seiten leicht zugänglich zu machen.

Auch bei den mobilen elektrischen Hubtischwagen sind Sonderausführungen möglich. Den Kundenwünschen werden kaum Grenzen gesetzt.

ATEX-Zonen-Klassifizierung von Hubtischen / EX Hubtisch

Die ATEX-Zonen-Klassifizierung für Hubtische ist das Wichtigste bei der Auswahl eines Hubtisches für gefährliche Umgebungen. Diese Klassifizierung, auch als Zertifizierung bekannt, wird in Industrien verwendet, in denen explosionsfähige Atmosphären vorhanden sind, wie sie beispielsweise in Chemieanlagen und petrochemischen Anlagen zu finden sind. In solchen Umgebungen können sich brennbare Gase, brennbarer Staub und Partikel verbinden und eine explosionsfähige Atmosphäre bilden. Geräte, die in solchen Situationen verwendet werden, sollten explosionssicher und funkensicher sein.

Es gibt verschiedene Zonen für elektrische Betriebsmittel, z. B. für explosionsgefährdete Umgebungen. Diese Zonen bestimmen die sichere Verwendung und Inbetriebnahme verschiedener Arten von elektrischen Geräten, wie z. B. Hubtischen. Ein als ATEX-Zone klassifizierter Hubtisch eignet sich für Installationen in einer Zone, die nach der Art der enthaltenen Gase und Stäube klassifiziert ist. Das Maluk Sortiment umfasst Hubtische für verschiedene ATEX Zonen. Zur Einhaltung der Sicherheitsvorschriften und zur Erleichterung der Inbetriebnahme werden die Tische mit einer umfangreichen Dokumentation und Betriebsanleitungen geliefert. Das Aggregat und die Steuerung werden außerhalb der EX-Zone aufgestellt.

Die ATEX-Zonen-Klassifizierung von Hubtischen kann die tägliche Arbeit mit einem Hubtisch in explosionsgefährdeten Umgebungen erleichtern. Hubtische, die gemäß ihrer ATEX-Zonen-Klassifizierung ausgelegt wurden, sind für den Einsatz in ATEX-Bereichen zugelassen.

Zufriedene Maluk Kunden

Kundenstimmen zu unseren Hubtischen

Unsere Firma ist von Maluk begeistert. Die Hubtische haben höchste Qualität. Die Preise sind auch o. k.

Arthur Probst

Die Maluk-Hubtische haben ein sehr gutes Preis-Leistungs-Verhältnis. Wir sind sehr zufrieden!

Sandra Peternell

Mir gefällt das Service und die schnellen Reaktionszeiten. Maluk kann ich gerne empfehlen.

Sascha Cerne

Die Arbeiter in unserem Maschinenpark sind von den Hubtischen begeistert. Sehr gute Qualität!

Thomas Koller

Maluk ist ein Kärntner Qualitätsunternehmen

Werden auch Sie ein zufriedener Maluk Hubtisch-Kunde!

Ein umfassender Leitfaden zu Hubtischen

Hubtische sind wichtige Geräte in industriellen, gewerblichen und privaten Umgebungen. Sie sind unverzichtbar für eine Vielzahl von Anwendungen und tragen zur Verbesserung der Effizienz und Produktivität bei. In diesem Artikel werden wir die verschiedenen Aspekte von Hubtischen eingehend erörtern, von ihrer Funktion und Bedeutung bis zu den verschiedenen Arten von Hubtischen und ihrem Einsatz in verschiedenen Branchen.

Was sind Hubtische und wie funktionieren sie?

Hubtische sind Geräte, die dazu dienen, Lasten auf eine bestimmte Höhe anzuheben. Sie sind mit Scherenbeinen konstruiert, die mit einer Plattform und einem Grundrahmen eines Hubtisches verbunden sind. Wenn sich die Scheren öffnen, steigt die Plattform vertikal an. Es gibt verschiedene Variationen von Scherenkonstruktionen, die verwendet werden, um die Plattform eines Hubtisches anzuheben und abzusenken.

Hubtische bieten eine effiziente Lösung für das Heben und Senken von schweren Lasten, was sie zu einem unverzichtbaren Werkzeug in vielen industriellen und gewerblichen Umgebungen macht.

Die Bedeutung von Hubtischen

Hubtische, wie die von Maluk, spielen eine entscheidende Rolle in vielen industriellen und gewerblichen Umgebungen. Sie ermöglichen es den Mitarbeitern, schwere Gegenstände zu heben und zu bewegen, ohne ihren Rücken oder ihre Muskeln zu belasten. Sie sind ergonomisch gestaltet, um Stress abzubauen und die Mitarbeiter produktiver zu machen. Hubtische vereinfachen alltägliche Aufgaben und steigern die Produktivität in einer Vielzahl von Anwendungen.

„Hubtische sind ein wesentlicher Bestandteil unserer Produktionslinie. Sie haben nicht nur die Effizienz gesteigert, sondern auch das Risiko von Arbeitsunfällen reduziert. Maluk hat uns dabei geholfen.“ – Produktionsleiter eines großen Fertigungsunternehmens.

Verschiedene Arten von Hubtischen

Es gibt verschiedene Arten von Hubtischen, die für unterschiedliche Anwendungen geeignet sind. Im Folgenden sind einige der gängigsten Arten aufgeführt, darunter der hydraulische Hubtisch und der elektrische Hubtisch.

1. Hydraulische Hubtische

Diese Art von Hubtisch, der hydraulische Hubtisch, verwendet ein hydraulisches System, um die Plattform anzuheben und abzusenken. Sie sind sehr leistungsfähig und können schwere Lasten mit Leichtigkeit bewältigen. Hydraulische Hubtische sind in verschiedenen Größen und Tragfähigkeiten erhältlich und können sowohl in industriellen als auch in kommerziellen Umgebungen eingesetzt werden.

2. Elektrische Hubtische

Ein elektrischer Hubtisch verwendet einen Elektromotor, welcher eine Spindel antreibt, um die Plattform anzuheben und abzusenken. Sie sind einfach zu bedienen und bieten eine präzise Kontrolle über die Hubhöhe. Elektrische Hubtische bzw. Spindelhubtische sind ideal für Anwendungen, die eine hohe Genauigkeit und Kontrolle erfordern.

3. Manuelle Hubtische

Manuelle Hubtische, die mit Hand- oder Fußpumpen betrieben werden, sind ideal für kleinere Aufgaben und Umgebungen, in denen kein Strom verfügbar ist. Sie sind kostengünstig und einfach zu bedienen, erfordern jedoch mehr körperliche Anstrengung als ihre hydraulischen oder elektrischen Gegenstücke. Diese Art von Hubtischen wird oft mit einem Handhebel betrieben.

Auswahl des richtigen Hubtisches

Die Auswahl des richtigen Hubtisches hängt von einer Reihe von Faktoren ab, einschließlich der Art der Anwendung, der zu hebenden Last und den spezifischen Anforderungen des Arbeitsplatzes. Sicherheitsstandards sind einige der Faktoren, die bei der Auswahl eines Hubtisches zu berücksichtigen sind.

- Tragfähigkeit: Die Tragfähigkeit ist ein wesentlicher Faktor bei der Auswahl eines Hubtisches. Sie müssen einen Hubtisch wählen, der in der Lage ist, die maximale Last, die Sie heben möchten, sicher zu tragen.

- Hubhöhe: Die Hubhöhe bezieht sich auf den maximalen Abstand, den der Hubtisch anheben kann. Sie sollte auf der Grundlage der spezifischen Anforderungen Ihrer Anwendung ausgewählt werden.

- Größe der Plattform: Die Größe der Plattform ist ein weiterer wichtiger Faktor. Sie sollte groß genug sein, um die Last sicher zu tragen, aber nicht so groß, dass sie zu viel Platz einnimmt.

- Art der Anwendung: Die Art der Anwendung kann auch die Auswahl des Hubtisches beeinflussen. Zum Beispiel sind manuelle Hubtische ideal für kleinere Aufgaben und Umgebungen, in denen kein Strom verfügbar ist, während elektrische oder hydraulische Hubtische besser für größere, leistungshungrige Anwendungen geeignet sind.

- Preis: Schließlich sollte der Preis auch bei der Auswahl eines Hubtisches berücksichtigt werden. Es ist wichtig, einen Hubtisch zu wählen, der innerhalb Ihres Budgets liegt, aber denken Sie daran, dass die billigste Option nicht immer die beste ist. Es ist oft besser, etwas mehr für ein qualitativ hochwertiges Produkt auszugeben, das langlebig und zuverlässig ist.

Einsatz von Hubtischen in verschiedenen Branchen

Hubtische werden in einer Vielzahl von Branchen eingesetzt, darunter:

- Produktion und Fertigung: In Produktions- und Fertigungsumgebungen werden Hubtische häufig verwendet, um schwere Maschinen, Ausrüstungen oder Materialien anzuheben. Sie ermöglichen es den Arbeitern, auf bequeme und sichere Weise auf diese Gegenstände zuzugreifen.

- Lager und Logistik: In Lagern und Logistikzentren werden Hubtische oft verwendet, um Paletten und andere schwere Güter zu heben und zu bewegen. Sie können auch als verstellbare Arbeitsplattformen für Arbeiter dienen.

- Bauwirtschaft: Auf Baustellen werden Hubtische oft verwendet, um schwere Baumaterialien anzuheben und zu bewegen. Sie können auch als verstellbare Plattformen für Arbeiter dienen, die in der Höhe arbeiten.

- Gesundheitswesen: In Gesundheitseinrichtungen werden Hubtische oft verwendet, um Patienten sicher und bequem anzuheben und zu bewegen. Sie können auch als verstellbare Betten oder Untersuchungstische dienen.

Sicherheit bei der Verwendung von Hubtischen

Die Betriebssicherheit ist ein zentraler Aspekt bei der Verwendung von Hubtischen. Es ist wichtig, sicherzustellen, dass der Hubtisch ordnungsgemäß gewartet und bedient wird, um Unfälle und Verletzungen zu vermeiden. Hier sind einige Sicherheitstipps für die Verwendung von Hubtischen:

- Stellen Sie sicher, dass der Hubtisch richtig installiert und gewartet wird. Regelmäßige Inspektionen und Wartungsarbeiten können dazu beitragen, potenzielle Probleme frühzeitig zu erkennen und zu beheben.

- Schulen Sie die Mitarbeiter in der sicheren Bedienung des Hubtisches. Sie sollten wissen, wie sie den Hubtisch richtig bedienen und welche Sicherheitsvorkehrungen sie treffen müssen.

- Lasten sollten immer sicher auf dem Hubtisch platziert und gesichert werden. Unzureichend gesicherte Lasten können herunterfallen und Verletzungen verursachen.

- Stellen Sie sicher, dass der Bereich um den Hubtisch frei von Hindernissen ist. Dies kann dazu beitragen, Unfälle und Verletzungen durch umfallende Gegenstände zu vermeiden.

Hubtische sind unverzichtbare Geräte und in vielen industriellen und gewerblichen Umgebungen unverzichtbar. Sie bieten eine effiziente und sichere Lösung für das Heben und Senken von schweren Lasten und tragen zur Verbesserung der Effizienz und Produktivität bei. Es ist wichtig, den richtigen Hubtisch für Ihre spezifischen Anforderungen zu wählen und sicherzustellen, dass er ordnungsgemäß gewartet und bedient wird, um Sicherheit und Langlebigkeit zu gewährleisten.